Why do dozens of companies all over the Czech Republic rely on the MES xMost production system?

Get control of your production – increase efficiency, reduce costs and minimize errors

Do you want to get production under control? That’s what you need unbiased data. Directly from the machines.

A production system is not a self-help solution that you plug into a machine and it’s taken care of. It is a tool that collects data in real time and displays it truthfully. Because in order to work on improvement, you need to know where your weak points are. Is it downtime? Do you care about availability? Quality? Are you wasting electricity? What about employee performance?

We automatically connect the collected data from the machines with the data from the operators, so you can evaluate both the machines and the workers. You can also supplement production data with information from your ERP system.

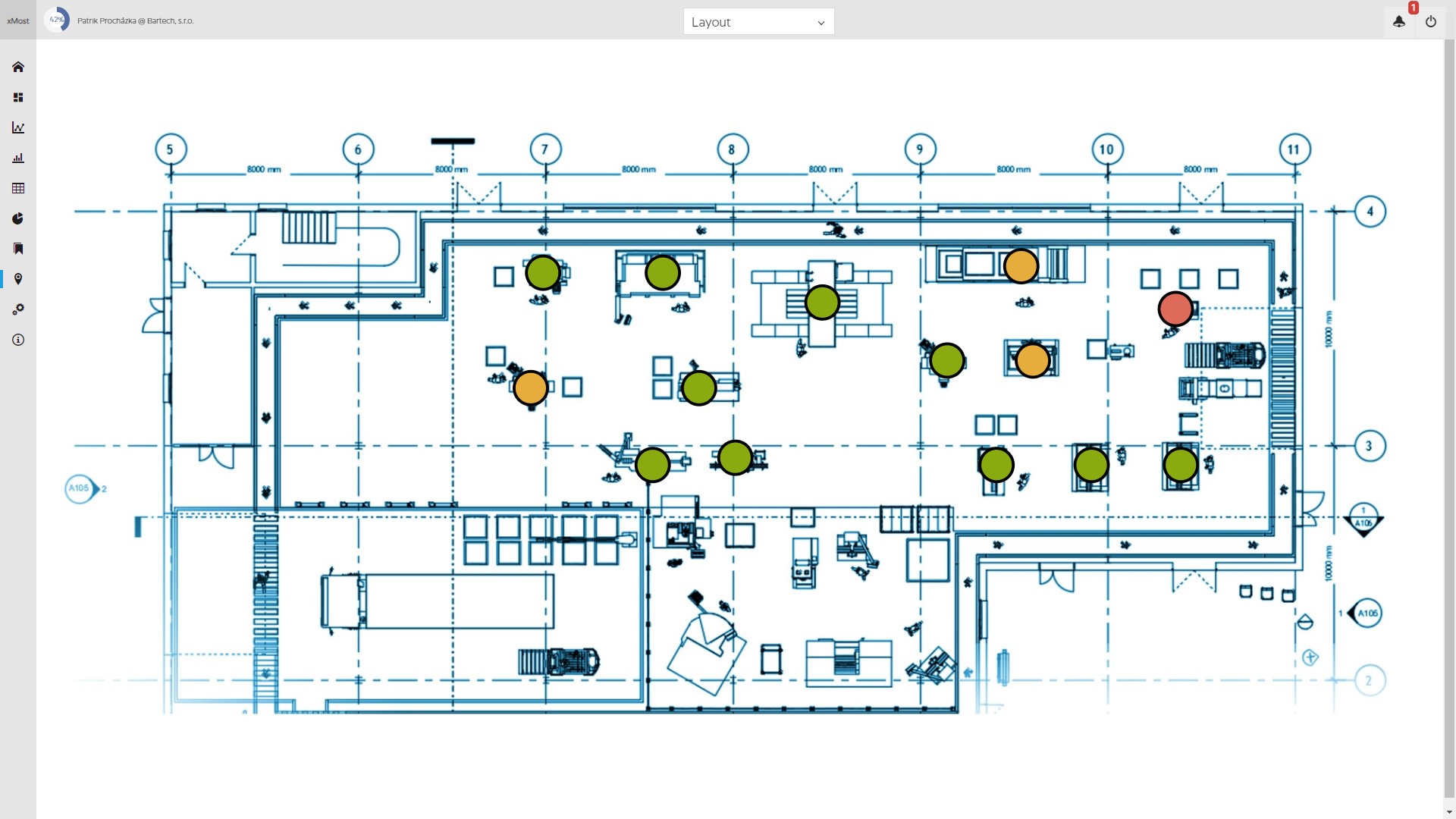

Together with other functions of the production system, such as the measurement of electricity consumption, a live layout of the production hall, digitized work orders, checklists for quality control on the touch terminal, you will get a tool that will open the door to the digital transformation of production and Industry 4.0 wide open.

YOU CAN SEE THE REAL RUNNING OF THE SYSTEM AFTER LOG IN HERE!

Request access by pressing the button below..

After sending your contact details, we will immediately send you a login and password.

Data Collection: Get an overview of production status

Machine monitoring and the collection of technological and user data is a springboard to process optimization. You get a true and quick overview of machines, orders, products and people with one click. And you can see them anytime and anywhere (on a mobile phone, LCD screen in the production hall, on a tablet and a terminal)

With xMost you can monitor any electrical production machine, the production system collects data using electrical impulses. We can also communicate with machines using MODBUS, SIEMENS S7, OPC and many other protocols.

Make informed decisions

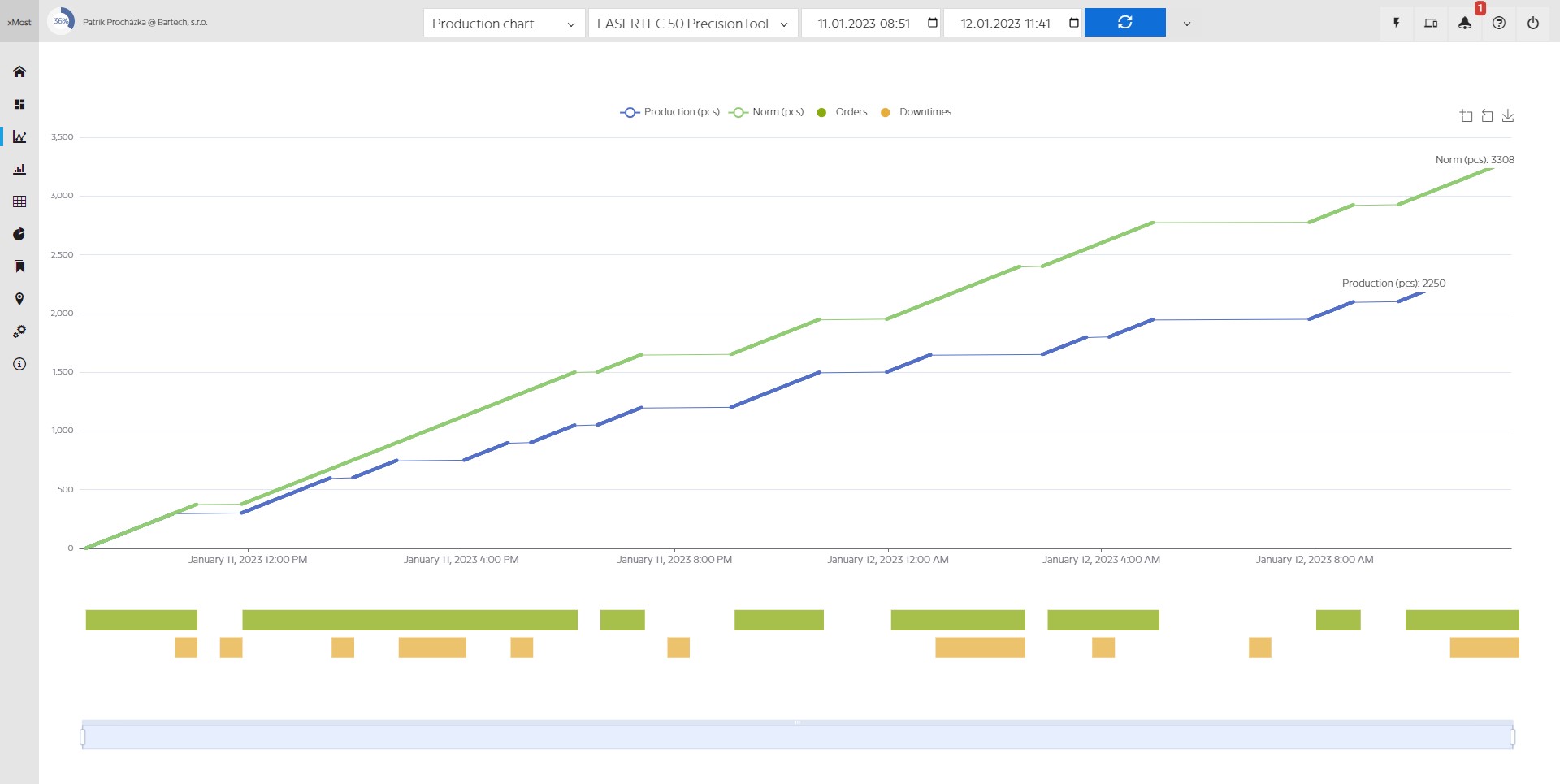

The best decisions are those based on accurate and up-to-date data. With MES xMost you can quickly and correctly react to situations. And above all to constantly improve. For example:

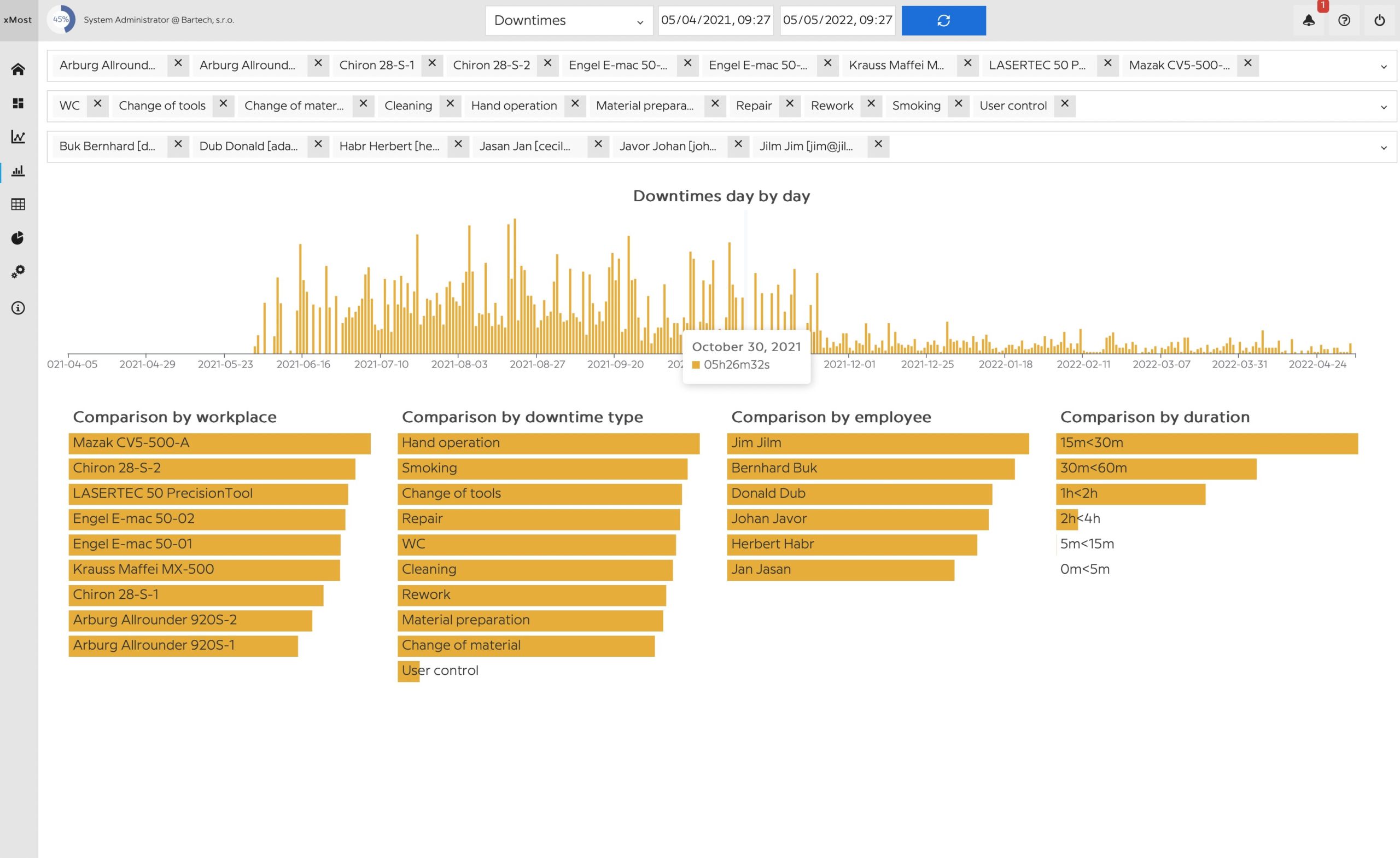

- you will increase the performance of the equipment due to the reduction of downtimes,

- you will increase the quality due to the reduction of rejects,

- you will better plan production and preventive maintenance,

- you eliminate the waste of resources (energy, material, money and employee potential).

Find trouble spots

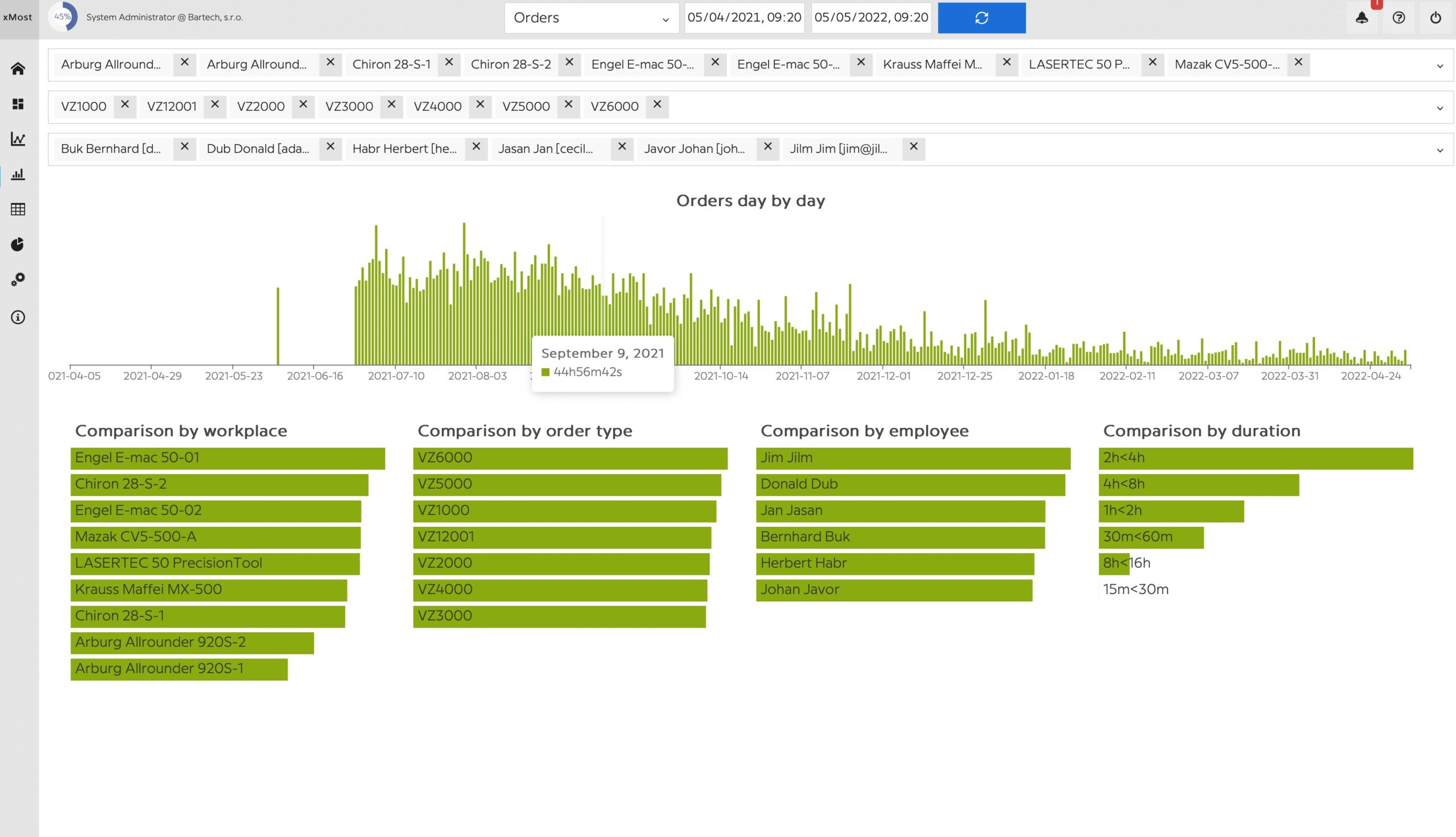

Simple production statistics are not enough to increase efficiency. The xMost MES system automatically analyzes most of the collected data, and you can easily identify problems based on reports. You can filter and compare data as needed, or create your own reports. This way you can easily uncover the reasons for waste and inefficiency, low quality, downtime and breakdowns.

- Stop wasting energy – xMost stores the consumption of electrical energy by workplace, machine, job, product and worker.

- Traceability – record data on products, raw materials, production lines and suppliers.

- Learn to plan preventive maintenance -– because xMost collects data directly from the machine, you can plan preventive maintenance based on it. Over time, you will learn to predict a possible malfunction, procure spare parts in advance and plan operations so that maintenance affects the production process as little as possible.

Don’t be taken by surprise

In the background of the system, an automatic check of pre-set critical events takes place. When they are activated, the system sends an alarm (e-mail, sms). Well-set alarms help on a daily basis. They monitor downtime, quality, preventive maintenance, work safety, availability and production status. You can simply rely on alarms and notifications.

ARE YOU LOOKING FOR A RELIABLE PARTNER IN MES SYSTEMS?

We are here for you.

Contact us and together we will find a solution that will exactly match your needs.