Production monitoring

xMost MES

The secret of successful production line: data collection and the MES system xMost

Production like in the palm of your hand

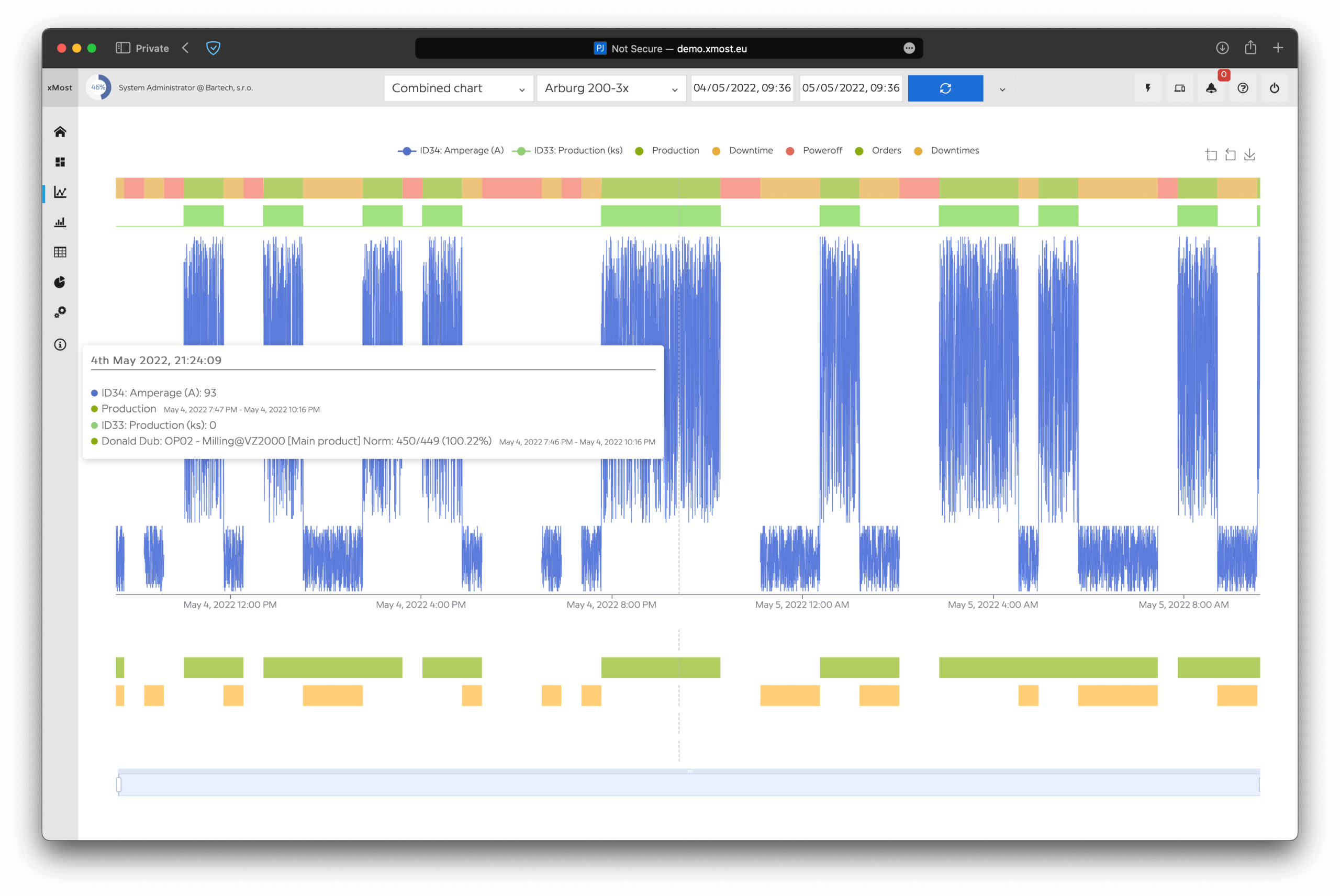

Keep an eye on your electricity consumption

Get your electricity costs under control. xMost tracks and evaluates machine consumption and assigns it to a workplace, job, employee or compares idle/production numbers.

xMost MES for any machine

xMost is universal. You can connect it to modern machines that communicate via the communication interface, even the oldest ones, where we collect data from the distribution box.

No regular charges

We deliver xMost to ownership, so you won’t pay any recurring fees to use the system.

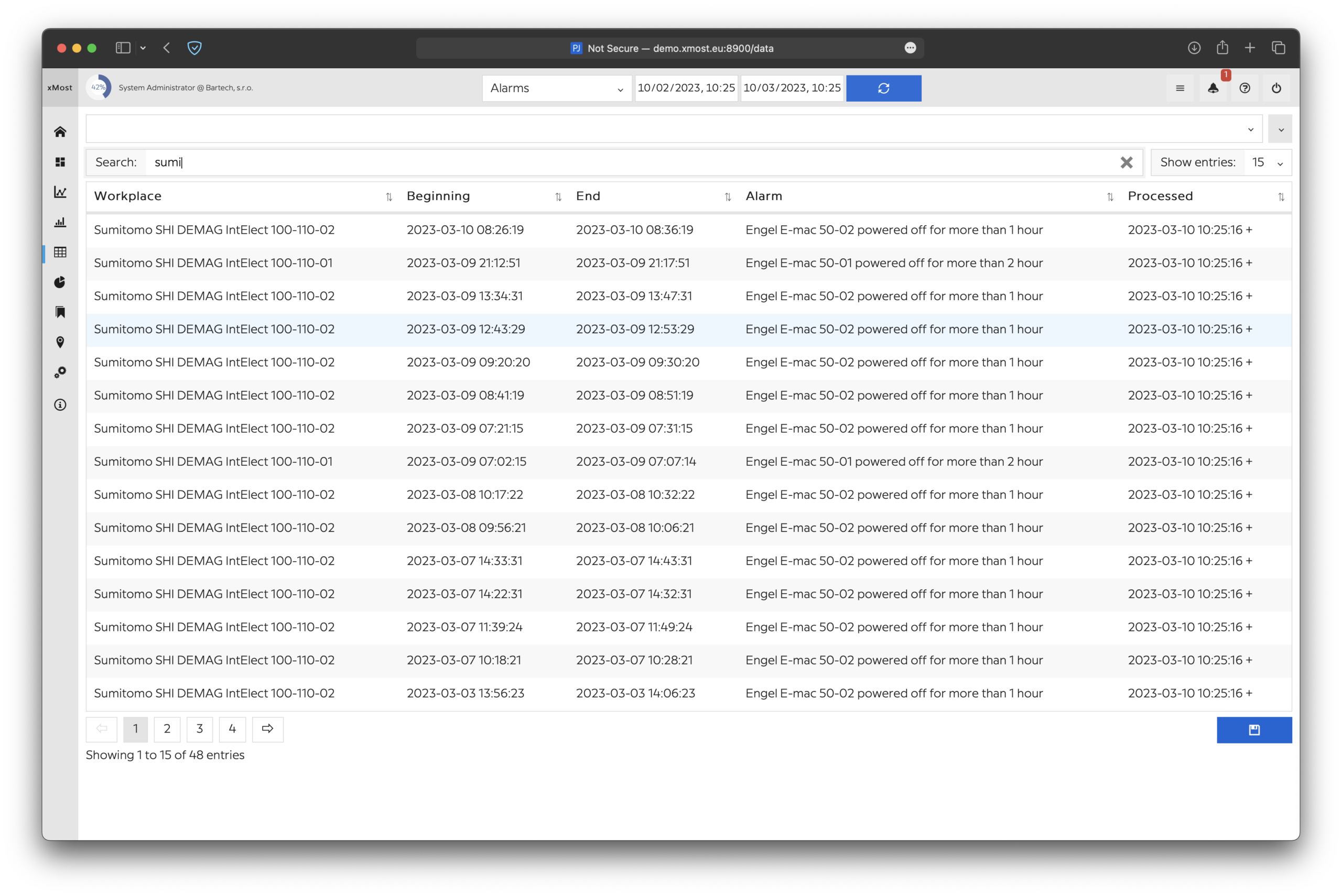

Automatic alarms and notifications

xMost will notify you by e-mail or SMS about any non-standard situation in production. Now you won’t be surprised by long downtimes or higher energy consumption.

Where can the xMost MES system help you?

Do you want to have an overview of production 24/7 and reveal weak points? Do you want to know the reasons for downtime, know where your production money is going and keep your employees under your thumb even during night shifts? And above all, to have true data in hand that will help you make the right decisions?

xMost collects and stores current production data and then clearly visualizes it in a user-friendly web application. So you have a true online overview of the state of production, including a comparison with history, accessible anytime and anywhere. You have the opportunity to step towards the digitization of production and Industry 4.0.

You can see the actual running of the system and data collection after logging in HERE. Request access by pressing the button below.

After sending your contact details, we will immediately send you a login and password.

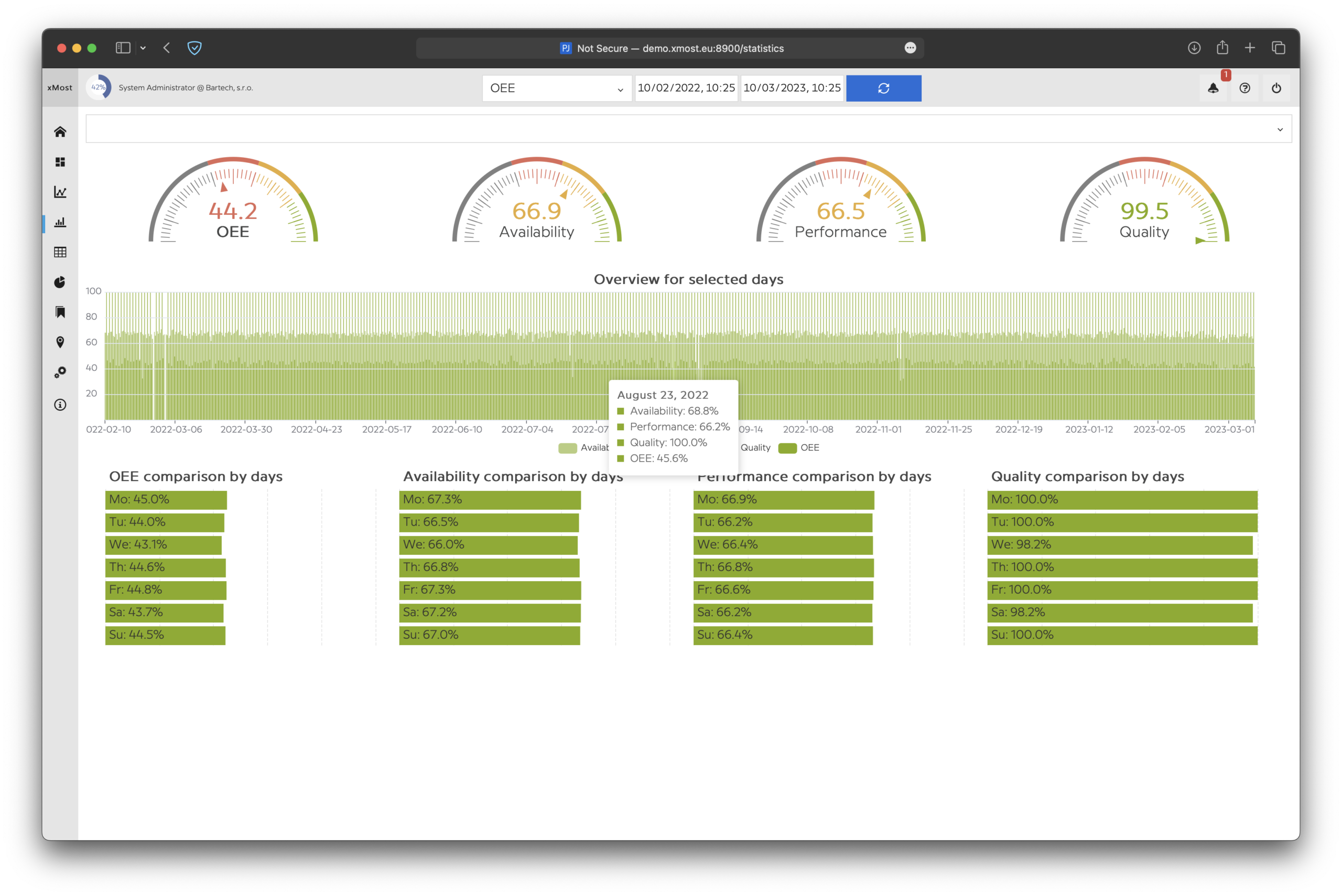

Production monitoring and data collection

Say goodbye to papers. With our solution, you will know exactly what is happening in your production. Minute by minute. From anywhere and on any device. Production status, downtime, breakdowns, OEE, electrical energy consumption of machines – everything at your fingertips.

MES xMost automatically collects data (technical and user) and clearly visualizes them. In addition, the picking unit counts the pieces, so you get rid of the dependence on operators to do the work alone, while comparing the actual production data with the production plan.

Traceability (back tracking)

Get full control over WHEN, WHERE, HOW and WHAT is and has been produced. MES xMost ensures that all collected production data has a time stamp, thanks to which you can trace back orders, downtimes, failures, errors, worker data and technological data.

(Not only) measuring electricity consumption

Our collection unit not only collects information about the operation of the machine, but also measures the machine’s electricity consumption. We can assign this to a workplace, job, product, operator or compare values in production/downtime.

We can equip the production machine with other sensors (temperature, pressure, shock, etc.). So you can have production in the palm of your hand with all the data and graphs.

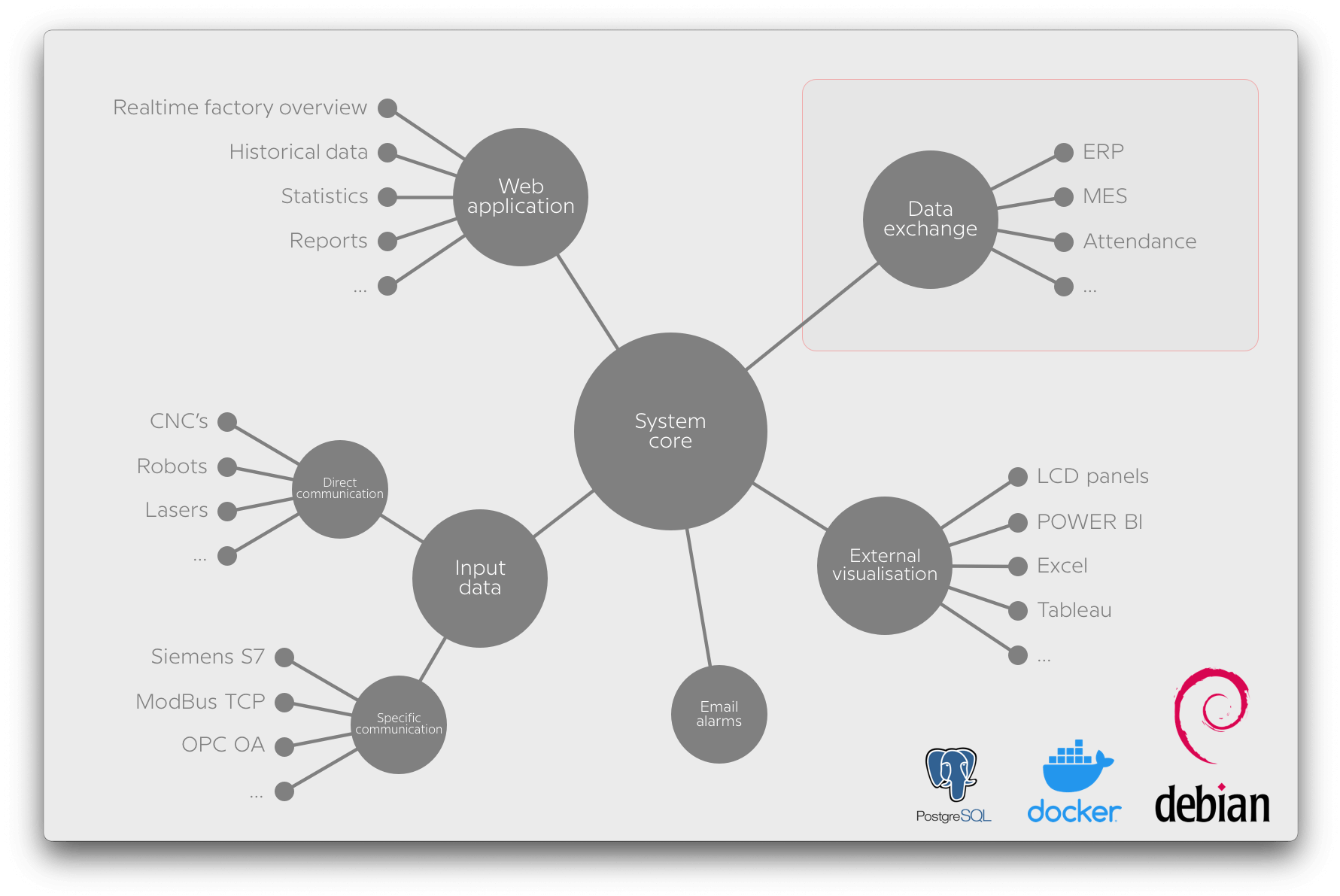

Integration not only with ERP

Do you have an ERP / attendance system / warehouse system and want MES? We usually connect them in several ways.

MES xMost pulls the data it needs from the ERP system itself (lists of people, orders, products) and at the same time provides the data. This is called fully automated production.

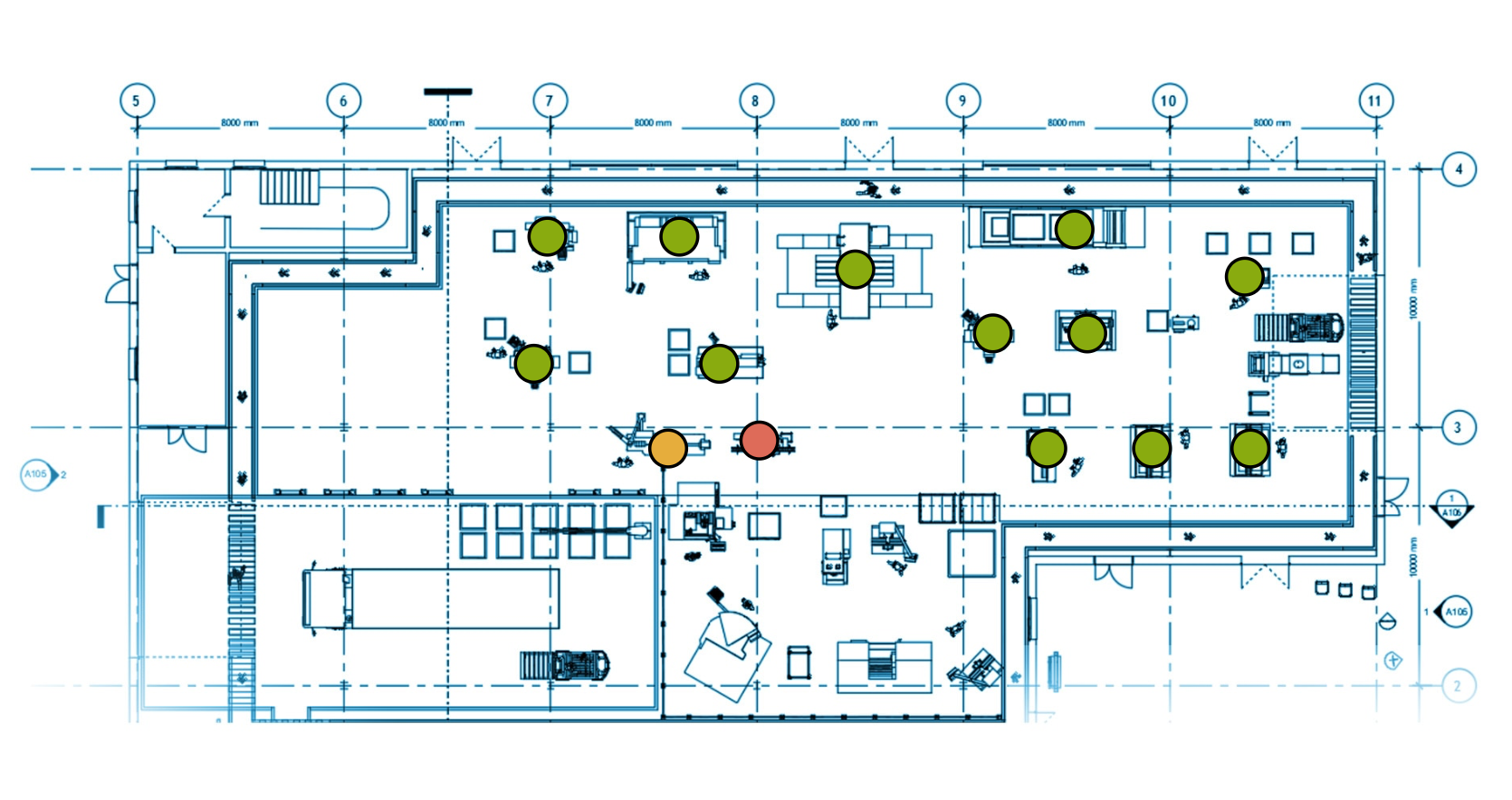

Visualization and reports on production status

To know means to see – clearly, for the first time and nowadays anytime and anywhere (for example, online on a mobile phone). You can now literally have your production hall in the palm of your hand with an interactive layout. On it you will see the status of individual machines in real time.

When compiling reports and dashboards, you can use preset templates, or create your own statistics and graphs in the reporting tool.

Quality control

Quality is key in production. Only a high-quality product meets customer expectations and acts as the company’s best business card.

MES xMost monitors the machine in real time, and by collecting and evaluating data, you can prevent the production of hundreds of defective pieces. Interactive checklists (conditional forms) then expand data recording by the human factor – they are called up to operators/controllers/masters depending on the type of order/product directly on the terminal and condition the continuation of production.

Preventive maintenance

Plan preventive maintenance efficiently and get service tasks and deadlines under control.

Thanks to the new function of the preventive maintenance plan and failure record on the tablet, you can solve maintenance directly in the field, without paperwork and with the possibility of collecting data directly from the machines. You will get an overview of the number of engine hours, preset control of critical events, alarms and notifications, breakdown statistics and much more. You maximize OEE, minimize production downtime. With xMost, you will have a modern and user-friendly tool in your hands, which will facilitate the work not only of maintenance workers, but also of managers.